PeroLaB® has the special property of absorbing radiation in the near infrared range (800 – 1200 nm) and in the UV range (250 – 400 nm) – the inorganic nano-absorber is almost colorless. The main property of converting the absorbed radiation (= light from lasers, LEDs or spotlights, for example) quickly and efficiently into heat makes the patented PeroLaB® an additive for a wide range of applications, such as laser welding of plastics and textiles, 3D printing, safety markings and light protection.

Due to the high melting point of over 2000 °C it can even be used in high-performance plastics, ceramics and metals

The heat can be used – locally and in a controlled manner – to heat up, melt, sinter, mark, heat or decompose materials as well as to stimulate and accelerate certain chemical processes.

Applied as a film, plastic sheet or as a solution on glass or plastic windows, PeroLaB® also protects against UV radiation and prevents the penetration of (warm) IR radiation through glass or plastic panes.

We also offer "tailor-made" products with PeroLaB®, which we develop in close cooperation with our customers for individual applications with special requirements.

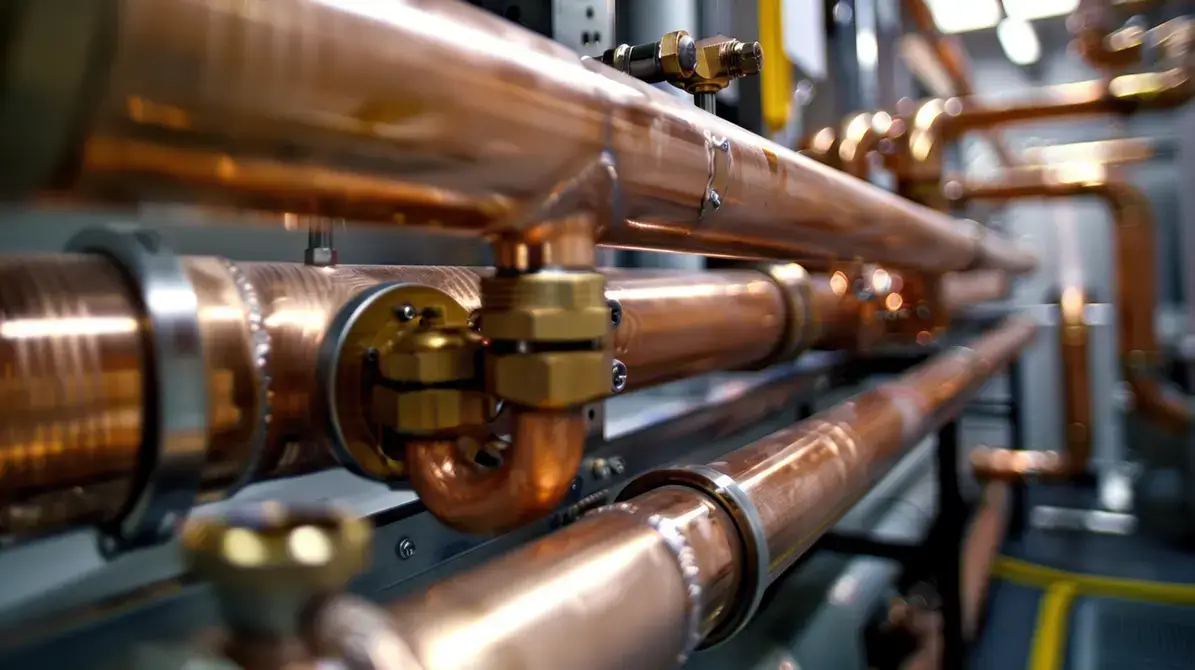

We are constantly discovering new applications for PeroLaB® – from heat recovery in heating systems to solutions against product piracy. We would be happy to help you solve your challenge.

We at Sindlhauser Materials are eager to support you in making your production processes more efficient with our absorber. As an ISO-certified materials developer and manufacturer we are looking forward to working with you to push the boundaries beyond today’s standard.

You are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information